Lately, the manufacturing sector has seen a tremendous transition, with new technologies and processes developing to boost efficiency. They also give way to lower prices and improve product quality. This has resulted in the growth of contemporary manufacturers who embrace automation, digitalization, and the interconnectedness of machines, systems, and people, also known as Industry 4.0.

What is Modern Manufacturing?

Modern manufacturing is the use of sophisticated technology and innovative techniques to manufacture components, products, and systems. It involves combining numerous technologies, such as computer-aided technologies, smart manufacturing, and additive manufacturing, to improve production efficiency and flexibility.

Contemporary manufacturing systems are characterized by their adaptable machinery, integration with supply chains, emphasis on speed and customization, and use of advanced technologies like AI.

Limitations in Traditional Manufacturing

The traditional industrial value chain was not intended to efficiently support a range of services beyond hardware. The industry has made significant improvements in agility, particularly in manufacturing and fundamental procedures. However, antiquated systems and divided teams make it difficult for manufacturers to swiftly introduce profitable new service lines to the market.

Manufacturers cannot simply extend their present service offerings to attain success. Rather, firms need to adopt agile development methods and organizational setups to stay competitive with industries that enhance customer value through servitization. With that in mind, these are the two areas on which manufacturers should concentrate in order to develop effective service models:

Change Your Customer Service Perspective

In the conventional customer service paradigm, consumers only contact manufacturers when they have an issue with a product. In many circumstances, this request may be sent through a channel partner. This contact initiates the following stages in service. The procedure frequently takes a long time and needs manual inputs, increasing the possibility of human mistakes and delays while the client waits for the repair.

Ensure Visibility Throughout Your Value Chain

The manufacturing sector has its complications. To function properly, a single plant requires the cooperation of several departments, equipment, data, technology, and employees. Large manufacturers have considerably greater complexity since they operate across continents and time zones while managing various suppliers and distributors.

Providing Value Beyond Traditional Products in Modern Manufacturing

Traditional manufacturing enterprises convert raw materials into consumable goods. They require area, labor, and a long-term plan to repay their investment. Both manual work and lower-skilled labor within a hierarchical organizational structure are common.

Traditional manufacturing is a traditional source of economic progress, despite the fact that the new high-performance computer technologies that will drive the next generation of manufacturing are closer than they appear. Traditional manufacturing relies on semi-skilled labor, high production, and close access to highways to function well.

Advanced manufacturing builds on existing innovation, making it only effective for companies with cutting-edge technology, such as medical, pharmaceutical, aerospace, and data collecting. Advanced manufacturing is built on customized production procedures, a competent workforce, digital infrastructure, and an open flow of information amongst everyone involved.

How to Implement Advanced Manufacturing

To comprehend best practices for adopting advanced manufacturing, it’s important to first grasp the value chain analysis steps. Cloud computing in advanced manufacturing can streamline marketing and sales processes by analyzing real-time global data, ensuring teams stay aligned and meet deadlines effectively.

- Advanced manufacturing, such as virtual reality prototypes, can help make the ideation process more efficient and practical.

- Advanced manufacturing, such as additive manufacturing, may reduce waste and improve accuracy throughout the design process.

- Advanced manufacturing in the form of composite materials may make raw material acquisition safer, simpler, and faster by employing only the elements required for the product and nothing else.

- Advanced manufacturing, such as laser welding or robots, can simplify and improve the production process.

- Advanced manufacturing in the form of cloud computing can facilitate marketing and sales processes by analyzing real-time global data, ensuring all teams remain aligned and meet deadlines punctually.

Technological Advancements in Modern Manufacturing

Manufacturing has evolved greatly from manual labor and traditional methods. Modern production has become more efficient, cost-effective, and environmentally friendly as technology has advanced. Let’s look at some of the important components of these technological advancements:

Internet of Things

The Internet of Things (IoT) refers to a network of connected devices capable of collecting and exchanging data. In modern manufacturing, IoT-powered solutions may be used to monitor production processes, maintain inventories, and gather product performance data.

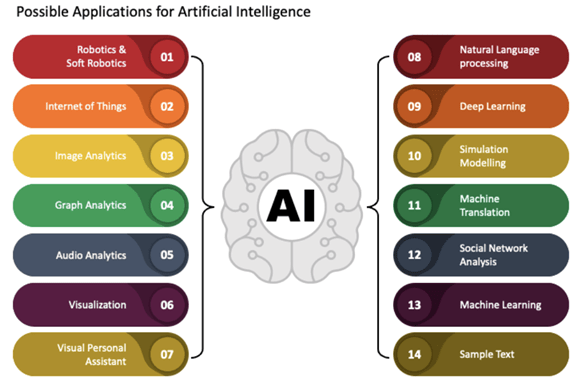

Artificial Intelligence

AI has the ability to transform industrial businesses. AI-powered systems may evaluate data and forecast outcomes, assisting firms in optimizing manufacturing processes and improving product quality.

Automation

Automation has significantly influenced modern production. Robots and automated systems have replaced manual labor in many manufacturing processes, leading to higher efficiency and lower production costs. Automation also improves product quality since machines can do jobs more accurately and consistently than people.

Conclusion

Modern production requires far more than simply producing goods. It involves providing value that extends beyond conventional notions of production and consumption. From customization and personalization to agility and flexibility, from using the power of digital technology to emphasizing sustainability and environmental responsibility, contemporary manufacturing is transforming industries and pushing innovation at every step. Manufacturers can stay ahead in a fast-evolving business landscape by embracing collaboration, co-creation, and servitization. Looking ahead, we can see that modern manufacturing has the capacity to produce value well beyond traditional borders.

Copyright © 2024 California Business Journal. All Rights Reserved.

Related Posts