The technological backbone of modern automation is increasingly defined by the sophistication of its components, among which servo controllers stand out due to their fundamental roles in various industries. Serving as the crucial nexus between mechanical action and digital instructions, these devices dictate the dynamics of modern manufacturing and design processes.

What Are Servo Controllers?

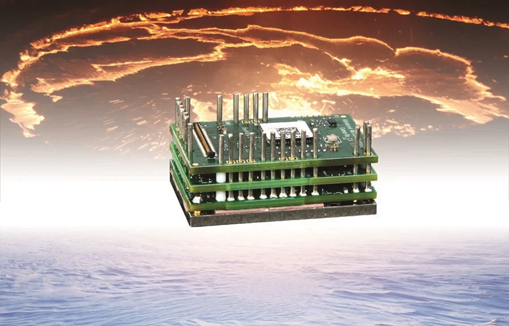

Servo controllers are intricate devices that manage the operation of a servo mechanism or servo motor in various applications. Typically, these controllers ensure the accurate performance of a servo system by adjusting the motion based on feedback signals. Their applications span numerous fields, illustrating their versatility and critical nature. With the help of AMC servo controllers automation processes become easier and precision.

Basic Components of a Servo Controller

- Motor Controls: Regulate the speed, direction, and position of the motor.

- Feedback Sensors: Measure the performance of the motor and adjust operations as needed.

- Drive Circuits: Power and control the motor.

- User Interface: Allows for programming and manipulation of controller settings.

Which Industries Heavily Rely on Servo Controller Manufacturers?

Servo controllers are instrumental across several key sectors, underlining their importance in the advancement of contemporary technologies and manufacturing processes.

Robotics

In robotics, servo controllers provide precision that enables robots to perform complex tasks from assembly to surgery. They are essential in applications requiring intricate movement control, from industrial robotic arms to autonomous vehicles.

Examples in Robotics

- Assembly Robots: Perform tasks with high precision, improving production quality.

- Surgical Robots: Offer enhanced dexterity and control, allowing for minimally invasive procedures.

Automotive Manufacturing

The automotive industry utilizes servo controllers to enhance the efficiency and precision of production lines. They are crucial in tasks that require exact movement and reliable repeatability.

Applications in Automotive Manufacturing

- Welding Robots: Ensure precise and consistent welding operations.

- Painting Robots: Provide uniform application of paint, crucial for quality control.

Aerospace

Servo controllers in the aerospace industry are critical for the accurate and reliable operation of equipment, from the manufacturing process to the operation of aircraft components.

Aerospace Applications

- Satellite Positioning: Ensures precise orientation of satellite components.

- Aircraft Manufacturing: Automates critical processes like drilling and riveting, enhancing safety and efficiency.

Consumer Electronics

The production of consumer electronics demands high precision and miniaturization, where servo controllers play a vital role by ensuring components are assembled accurately.

Examples in Consumer Electronics

- Smartphone Assembly: Robots equipped with servo controllers assemble small, delicate parts with high precision.

- Computer Manufacturing: Ensures precise and efficient assembly of components.

Entertainment Industry

In entertainment, servo controllers are used in animatronics and special effects to create realistic movements and effects that captivate audiences.

Entertainment Applications

- Animatronics: Bring lifelike movement to creatures in theme parks and movies.

- Stage Effects: Coordinate complex sequences for live performances.

Medical Equipment

Precision and reliability are crucial in medical equipment, where servo controllers ensure that devices operate safely and effectively.

Medical Device Applications

- Diagnostic Machines: Provide precise movement necessary for imaging technologies.

- Surgical Instruments: Enhance the capabilities of devices used in complex medical procedures.

Why Are Servo Controllers Critical for These Industries?

The adoption of servo controllers across industries highlights their significance in enhancing precision and reliability, crucial attributes that directly impact production quality and efficiency.

Enhancing Precision in Manufacturing

Servo controllers significantly improve the accuracy of manufacturing processes, resulting in products that meet stringent quality standards.

Benefits of Enhanced Precision

- Reduced Waste: Higher accuracy means fewer materials are wasted.

- Improved Product Quality: Consistent production standards enhance product reliability.

Increasing Production Speeds

By optimizing the speed of operations, servo controllers not only increase output but also reduce the time to market for many products.

Customization Capabilities

The adaptability of servo controllers allows for easy customization of operations, catering to the specific needs of different products and markets.

What Are the Advantages of Using Servo Controllers?

The implementation of servo controllers brings numerous benefits that directly contribute to the operational excellence of industries.

- Precision: Ensures components are produced or operated with high accuracy.

- Efficiency: Improves the speed and reduces the waste of manufacturing processes.

- Adaptability: Allows for easy adjustments to meet varying production demands.

- Scalability: Can be scaled up or down depending on the size and scope of operations.

Challenges Faced by Industries Using Servo Controllers

Despite their advantages, the use of servo controllers comes with challenges that industries must continually address to maintain operational efficiency.

Maintenance and Upkeep

Servo controllers require regular maintenance to ensure they remain efficient and effective.

Typical Maintenance Requirements

- Routine Inspections: Regular checks to ensure all components function correctly.

- Software Updates: Keeping the software up-to-date to enhance functionality and security.

Technological Advancements

Rapid advancements in technology necessitate continual updates and adjustments in servo controllers to keep up with industry standards.

Integration Issues

Integrating new servo controllers with existing systems can pose challenges, particularly in terms of compatibility and disruption to current operations.

Future Trends in the Use of Servo Controllers

The future of servo controllers appears robust, with ongoing innovations expected to drive further advancements in their capabilities and applications.

Innovations in Servo Technology

Emerging technologies are likely to revolutionize how servo controllers are used, enhancing their efficiency and the scope of their applications.

Increasing Automation Demands

As industries push for more automation, the role of servo controllers is set to become even more central, driving the need for more sophisticated and capable devices.

How to Choose the Right Servo Controller Manufacturer?

Selecting the right manufacturer is crucial for ensuring that the servo controllers meet the specific needs of an industry or application.

Factors to Consider

- Technical Specifications: Must meet the operational requirements of the application.

- Supplier Reliability: The manufacturer’s reputation for quality and service.

Conclusion

Servo controllers are not just components but are foundational elements that will continue to shape the landscape of modern industries. Their role in enhancing precision, efficiency, and adaptability makes them indispensable in the age of automation. As technology evolves, so too will the capabilities and applications of servo controllers, ensuring they remain at the heart of industrial innovation.

Copyright © 2024 California Business Journal. All Rights Reserved.